Last summer (So this article was written about a year before publishing...) Anne Field posted a good blogtext in her blog. I interpreted it so that it is about learning experiences, practice, effort and doing your own work in general. I thought the article was so good that it should be saved somehow, to be easy to find later, so I linked it to my blog and commented on the subject(s) while chatting with an American friend, LittleYoungOne, in Discord.

|

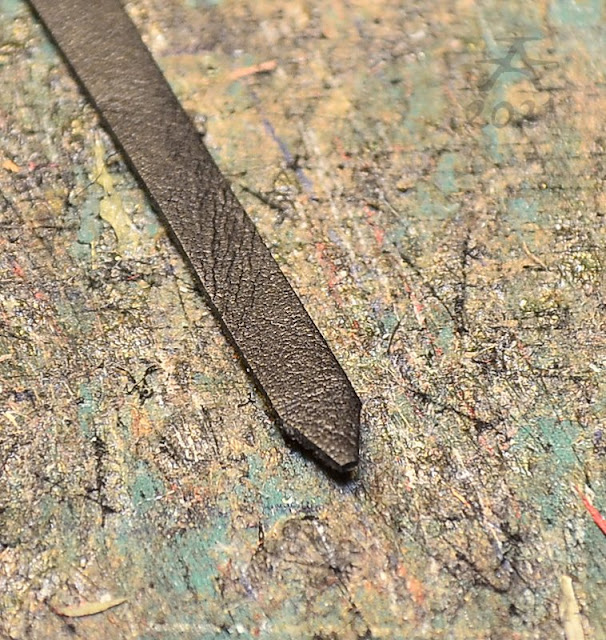

| Not So Black, a draft stallion from 2020. |

Here comes my comment speech:

What I got out of that post was how Anne emphasized that you can't trick when you want to do something well. Tutorials, instructions and answered questions from others will help, but the only thing which truly helps you learn is making the thing you are working on.

|

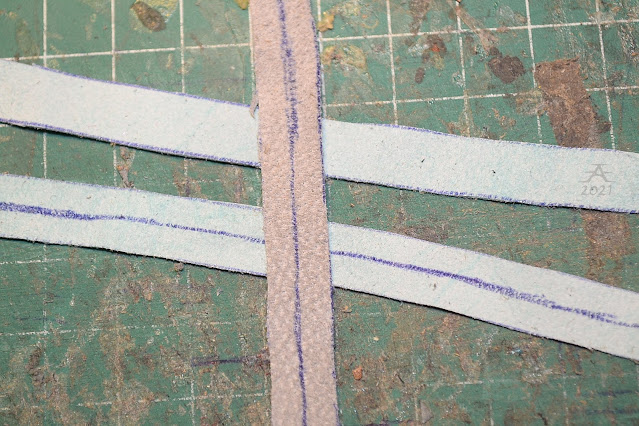

| Practicing to cut slots (for noseband hangers) in split crownpieces before doing the same for actual split crownpieces. |

|

| ...it worked! |

Also being afraid of fail is not an excuse. You will fail a lot during your practice sessions, get a ton of ugly stages and so on. What's the key to solve those? Continue to create. The ugly stages and fails are not going anywhere - they can only teach you to improve and eventually push through them and finish your work.

|

| In 2016, I asked and got taught how to braid. It may be the only "textile craft" I can enjoy, which shows in the number of ropes I've braided serially since then. |

And then about competitions and chasing prizes: If one participates in a show or competition, they should be totally okay with the possibility that they will not win. Everyone can't win, but most do good stuff to try with. The idea should never be winning, but participating, trying your best and figuring out what you can do, learn more. Compete against your previous works, if something has to be competed against.

What works for me, is thinking that "if I do this for my friend, it has to be the best I can do". This is how my bridles and halters are in the stage they are in at the moment. I started making tongue buckles to bridles, developed the bit hooks and bothered to figure out nosebands because I made a bridle for Kave in 2017. Basically I could say that I wanted to impress my friend with... skill? What?

In 2021 my Swedish hobby friend, Decors, asked if I could do tack to donate for a Swedish liveshow, Vattenshow, whose co-hostess she is. Of course I said that yes, I can make a few halters. Among the batch to be donated, I also wanted to make pieces for both of the hostesses. For Decors I made also a bridle and some bits to go with it. The difference between my oldest proper bridle and this is like between night and day.

|

| The bridle from June 2021, which moved to Sweden. |

What else can I say? I have wanted to write about this stuff for ages! But blogging is hard. While it can be hard to believe, I am not a writer, after all. (I do blog stuff or story/world texts almost daily, and draw very very seldom these days... But yep, I am not a writer.) I am a visual artist, a drawer. I also can do painting if I bother to. Watercolors are nice. So are makeup sponge tools when you use them on graphite - which is the only use I have ever had for them.

|

| A travel set of watercolors and tank brushes (brushes which have soft, hollow barrel) pair very well together. |

"What else"... Uh oh. I figured out that this is actually a good spot to mumble about my art life even further. I've drawn my entire life, and cannot remember the time I first scribbled something which should look like an animal or whatever the topic was (I remember drawing a carrot in kindergarten). I never drew with the idea that I "could become an artist". I just drew because it was a natural part of my life. It IS a natural part of my life.

Due to having drawn animals from that young age, I have an odd angle towards those who first grow up and only then decide to start drawing. Good luck with practice... It is a lot of work. I can say I have an advantage here. Though, it does not mean I could be good. I have seen so many beginners being great in what they do. Meanwhile I usually stop thinking good about my own works after each doodle gets a couple of years old or if I can see it all the time.

|

| Outdated thumb rats, since 2014. |

I often wonder what life could be like if I didn't draw or do my model horse stuff myself. Good stuff is pricey! (I guess my art room could also look very different than what it is. Supplies take a lot of space, so do projects and finished works...)

What could life be with aphantasia, as well? I can't imagine the lack of visual imagination; meanwhile I see everything in my mind. One ridiculous brain image I have had was about lemons flying downstairs with mosquito wings - thanks to how my dad tried to describe he had mosquitoes in his room. Don't ask how he managed to call them lemons, I have no idea. But I sure have some oddly rich hyperphantasia. I can see worlds while in the shower, and forget I even exist.

There was a time I wanted to learn to draw horses as properly as was possible. I became an anatomy freak. Eventually I also learned that realistic and semirealistic drawing styles are my thing, while I also wanted to develop my personal way to stylize "cartoony" equines. The latter went so that the anatomy had to work, but stylizing to some degree had to be possible, too. I have a ton of good memories of those years, but most of the doodles are not worth seeing... Of course.

Once I also decided to test if I can resculpt a toy horse in the BH-style, which is how I called my cartoony style. Now when I think it, it's strangely absurd and, ummmm... Impressive, in the sense that it really happened. I couldn't do that today. It's the same thing as what happened to my tack: I made a lot of Schleich scale tack at some point, learned to enjoy it, then switched to traditionals and no longer understood why and HOW anyone can enjoy crafting mini scale tack. It was impossible, and still is.

|

| I never knew my first(?) buckles with moving tongues were in a Schleich scale bridle, and I don't even know the year this is from. |

My drawer background was why I got into model horse customizing ages ago. It was the idea that I could really make a model horse, not only buy it. By customizing I was no longer dependent on what factories provided. Buying commissions from others was never an option - because I never knew anything like that even existed!! And well, I still like to do my own stuff, anyway... Not that I could not want to have others' works as well. Collecting others' tack and customs is a nice way to learn something new and see different angles of doing things.

But the bond between you and your own work is something which you can never have with a thing you did not make. It also feels nice to be able to say that "Yea, I did all the stuff in this photo." (Shows don't exist here.)

Since I probably didn't make any sense with most of this text, I will continue to comment on other stuff. It's close to the topic, of course. How can people be so crazy about winning, indeed? I have never been that much into participating in anything. I'm not a prize chaser. Shows (even photo shows) have never been my main motivator to learn to make model horse stuff. Good horses, paintjobs, tack, dolls, performance setups... Nope, never done those with showing in mind. And then the rare time I bother to try my luck in something, it even didn't require crafting on anything but just writing a little - and then I won! That made this little pessimist super happy. I still can't understand that it happened.

|

| Tripworthy, my Braymere giveaway marwari. |

Anyway. I wonder how much and how far could things have developed in the hobby if there were no shows, and especially, if the shows were not about competiting against others... This one has prettier horse, this one has the most blingy set of tack, here's a cool scene, aaand... So. How far can you go? What this logic has taught me about my species, is, that humans have an odd natural tendency to compete and try to win... It has to be natural.

I also want to say one more thing to the practice topic. I have found out that maybe I am unusual in the sense that I am less afraid of trying new techniques and tools when it comes to arts and photography. I struggle to start drawing anything I haven't drawn before (it is annoying, I wish I could draw many different species of animals), but I probably have tested various techniques and tools in more relaxed sense than most people I've talked about this with. I don't understand why it is like this. People are afraid of using a lot of colors, contrast, mixed media... They're afraid of shading with strong hand or exaggerating anatomy and expressions. And some are very afraid of starting their model horse customizer career.

|

| I brainwashed Kave into painting, taught her about how I layer colors, and her very first (very first!) repaint was this stunning tinker stallion. His name is Abundiantus Fructum. Photo by Kave. |

To say it simply, I do my all to kick encourage my buddies to try new things and hopefully make them go crazy and enjoy it. This happened with Kave and went successfully, so I am positive that my other hobby friends can start a model horse artist career too.

One thing I have wondered a lot is a stupid habit I have. Sometimes I find a way to do something, then go "nope, it's too much of work" or "that part will be weak" and it basically prevents me from trying it. Then when I finally give it a go, I probably get surprised and realise how much more sense everything makes when there is one more step in the process. It can both make the product better and also make me value my own work more than before. My halters are often better when they have paddings in the nosebands, and I always like my dolls better when I bother to paint shadings to their bodies.

I also have learned that my brain needs challenges, and even works to stress about. One example of this could be one of my dolls, who is based on a character I designed in 2011. That doll had to turn out perfectly enough. It went almost so, but he's no way ideal... Of course. Finishing complex projects feels good afterwards. Another example of this could be my thumb rat cages. Sometimes I assemble them from a million of different pieces just because I enjoy the process. Weird.

|

| Enjoyable. |

Do your effort.